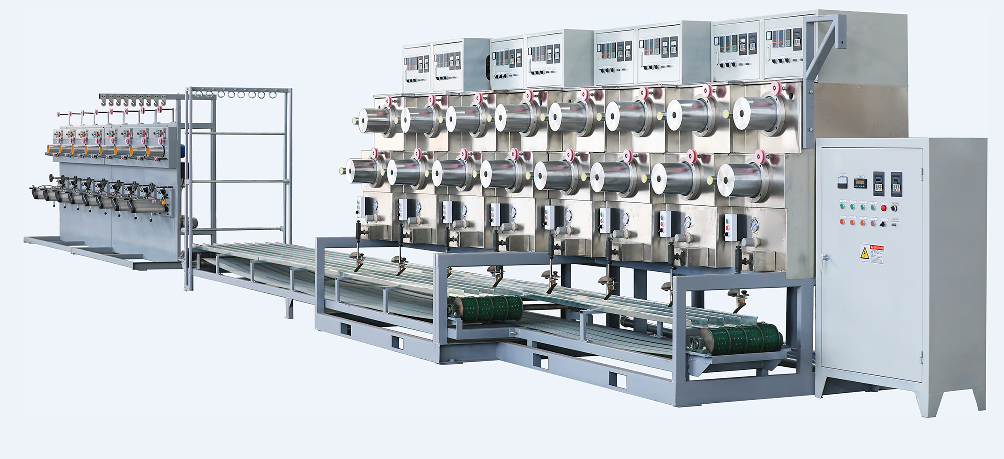

ST-QCS series plastic lawn one-step bending silk production line, the unit in the use of Germany, South Korea's advanced technology on the basis of their own comprehensive design of a one-step lawn multi-root monofilament irregular bending deformation production equipment;

Suitable for the production of polypropylene (PP), polyethylene (PE), nylon 6 (PA6) as raw materials for the production of artificial turf curved wire.

| Model | 65×33 | 70×33 | 80×33 | 90×33 |

|---|---|---|---|---|

| Main Raw Materials | PP, PE | PP, PE | PP, PE | PP, PE |

| Twin - Screw Extruder Production Capacity (kg/h) | 40 - 80 | 60 - 100 | 80 - 150 | 100 - 180 |

| Drive Motor (kw) | 22 | 30 | 37 | 45 |

| Screw Diameter (mm) | Φ65 | Φ70 | Φ80 | Φ90 |

| Length - to - Diameter Ratio (L/D) | 33:1 | 33:1 | 33:1 | 33:1 |

| Screw Barrel Material | 38CrMoAlA | 38CrMoAlA | 38CrMoAlA | 38CrMoAlA |

| Screw Speed (rpm) | 0 - 80 | 0 - 80 | 0 - 80 | 0 - 80 |

| Maximum Line Speed (m/min) | 400 | 400 | 400 | 400 |

| Roller Length (mm) | 700 | 700 | 800 | 900 |

| Draw Ratio | 3 - 5 | 3 - 5 | 3 - 5 | 3 - 5 |

| Number of Spinnerets (units) | 16 - 18 | 18 - 24 | 24 - 32 | 32 - 36 |

| Number of Filaments per Spinneret | 64 - 72 | 72 - 96 | 96 - 128 | 128 - 144 |

| Number of Winding Spindles | 16 - 18 | 18 - 24 | 24 - 32 | 32 - 36 |

| Installed Power (kw) | 280 - 290 | 320 - 360 | 390 - 450 | 480 - 510 |

| Actual Power (kw) | 168 - 175 | 192 - 216 | 234 - 270 | 288 - 306 |

| Overall Dimensions of In - Line Type (Length×Width×Height) m |

34×5×3 36×5×3 |

36×6×3 39×6×3 |

40×6×3 44.5×6×3 |

45×6×3 47×6×3 |

| Overall Dimensions of L - Type (Length×Width×Height) m |

28.5×8×3 30×8×3 |

30.5×8×3 34×8×3 |

34.5×8×3 38×8×3 |

39.5×8×3 41.5×8×3 |

●Double roller traction heating control to reduce the water content of the yarn, so as to achieve better stability to improve product quality;

●The air change adopts constant temperature hot air heating system, air pressure size adjustable system, high precision of temperature control and stable air pressure during high speed operation;

●The cooling conveyor belt has air ventilation holes to ensure the cooling effect.

The winding adopts an adjustable linear speed traction device. The coiling has a separate frequency conversion automatic constant tension control system. The finished product has advantages such as uniform tension and good forming.