ST-QCS series plastic lawn one-step bending silk production line, the unit in the use of Germany, South Korea's advanced technology on the basis of their own comprehensive design of a one-step lawn multi-root monofilament irregular bending deformation production equipment;

Suitable for the production of polypropylene (PP), polyethylene (PE), nylon 6 (PA6) as raw materials for the production of artificial turf curved wire.

| Model | 65×33 | 70×33 | 80×33 | 90×33 |

|---|---|---|---|---|

| Main Raw Materials | PP, PE | PP, PE | PP, PE | PP, PE |

| Production Capacity of Twin Main Machines (kg/h) | 40 - 80 | 60 - 100 | 80 - 150 | 100 - 180 |

| Drive Motor (kw) | 22 | 30 | 37 | 45 |

| Screw Diameter (mm) | Φ65 | Φ70 | Φ80 | Φ90 |

| Length - to - Diameter Ratio (L/D) | 33:1 | 33:1 | 33:1 | 33:1 |

| Screw Barrel Material | 38CrMoAlA | 38CrMoAlA | 38CrMoAlA | 38CrMoAlA |

| Screw Speed (rpm) | 0 - 80 | 0 - 80 | 0 - 80 | 0 - 80 |

| Maximum Line Speed (m/min) | 400 | 400 | 400 | 400 |

| Roller Length (mm) | 700 | 700 | 800 | 900 |

| Draw Ratio | 3 - 5 | 3 - 5 | 3 - 5 | 3 - 5 |

| Number of Spinnerets (units) | 16 - 18 | 18 - 24 | 24 - 32 | 32 - 36 |

| Number of Filaments per Spinneret | 64 - 72 | 72 - 96 | 96 - 128 | 128 - 144 |

| Number of Winding Spindles | 16 - 18 | 18 - 24 | 24 - 32 | 32 - 36 |

| Installed Power (kw) | 280 - 290 | 320 - 360 | 390 - 450 | 480 - 510 |

| Actual Power (kw) | 168 - 175 | 192 - 216 | 234 - 270 | 288 - 306 |

| Overall Dimensions of In - Line Type (Length×Width×Height) m |

34×5×3 36×5×3 |

36×6×3 39×6×3 |

40×6×3 44.5×6×3 |

45×6×3 47×6×3 |

| Overall Dimensions of L - Type (Length×Width×Height) m |

28.5×8×3 30×8×3 |

30.5×8×3 34×8×3 |

34.5×8×3 38×8×3 |

39.5×8×3 41.5×8×3 |

●Double roller traction heating control to reduce the water content of the yarn, so as to achieve better stability to improve product quality;

●The air change adopts constant temperature hot air heating system, air pressure size adjustable system, high precision of temperature control and stable air pressure during high speed operation;

●The cooling conveyor belt has air ventilation holes to ensure the cooling effect.

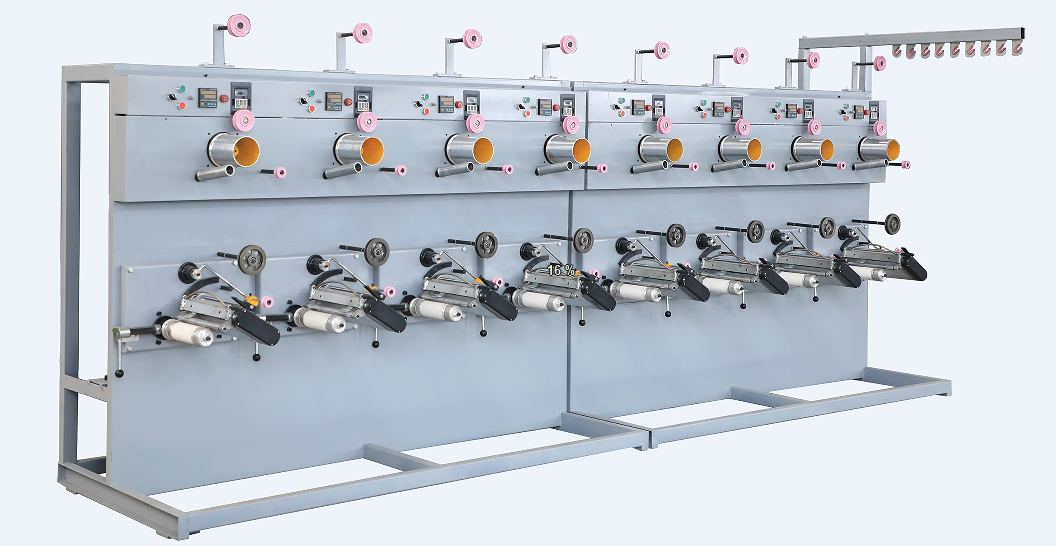

Winding adopts adjustable line speed traction device. Curl individual frequency conversion automatic constant rising force control system. The finished products have the advantages of even rising force and good shaping.