Application Prospects of Rewinder Machines: Powering Efficiency Across Diverse Industrial Sectors

The packaging industry stands as the largest and most dynamic application field for rewinder machines, driven by global e-commerce growth and demand for high-quality packaging materials. Rewinder machines are critical for processing core packaging products—including plastic stretch films (for pallet wrapping), adhesive tapes (masking tape, packing tape), and labels (shipping labels, product stickers)—by converting large master rolls into smaller, user-friendly sizes. Traditional manual cutting and winding lead to uneven roll edges and material waste, but rewinder machines ensure consistent tension, smooth edges, and precise roll diameters. They also adapt to diverse packaging needs: small businesses use compact semi-automatic models for low-volume label rewinding, while large logistics firms rely on high-speed automatic machines to handle massive rolls of stretch film, cutting down packaging time by 40% or more.

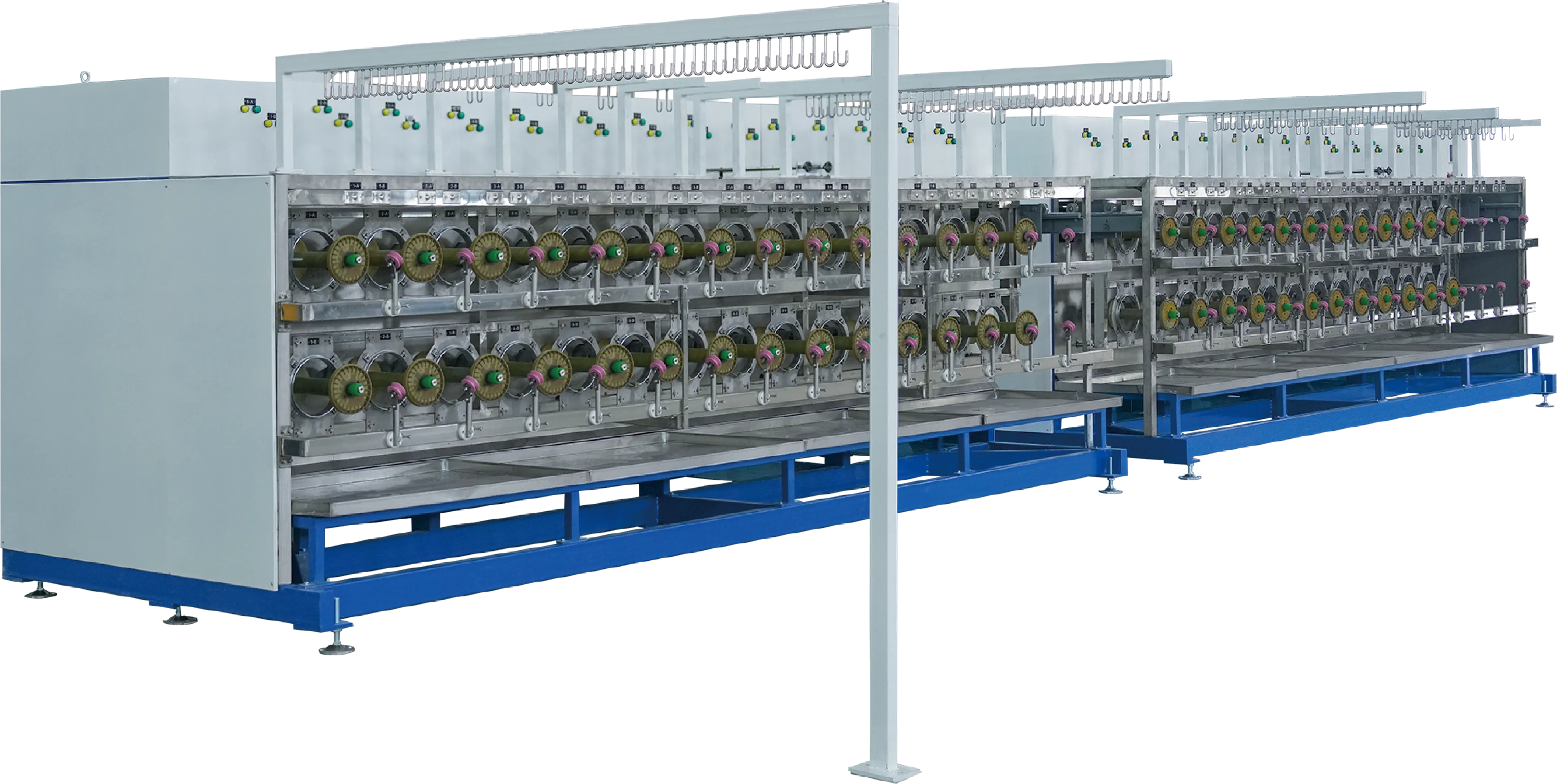

The textile and garment industry is a core application area, where rewinder machines address the industry’s need for uniform, easy-to-use thread and fabric rolls. Textile manufacturers use these machines to rewind bulk yarns (cotton, polyester, nylon) from large cones into smaller spools compatible with sewing machines, knitting machines, and embroidery equipment. They also process finished fabrics—such as cotton cloth or synthetic textiles—into rolls of specific lengths for garment cutting, avoiding the tangles and uneven tension that plague manual rewinding. For specialty textiles, like those used in sportswear (moisture-wicking fabrics) or industrial textiles (heavy-duty canvas), rewinder machines handle delicate or thick materials without damage. As the textile sector shifts toward customization, rewinder machines’ ability to support both small-scale and large-scale production makes them indispensable.

High-precision specialized industries are fast-expanding application prospects for rewinder machines, as these sectors require strict compliance with industry-specific standards. In the medical field, rewinder machines process sterile materials like surgical tapes, medical bandage rolls, and even fine threads for surgical sutures—they operate in dust-free environments and maintain ultra-consistent tension to avoid material contamination or breakage, meeting FDA and CE medical standards. The electronics industry uses rewinder machines for thin, insulated wires (e.g., enameled copper wire for microchips, headphones, and sensors), where even minor tension variations could disrupt electrical conductivity. Additionally, the paper industry relies on them to rewind tissue paper, toilet paper, and packaging paper into consumer-sized rolls, with advanced models integrating defect-detection technology to remove imperfect sections. As these high-value sectors grow (e.g., global medical device sales to reach $800 billion by 2030), the demand for precision rewinder machines will rise significantly.